DO Qualification Kit provides documentation, test cases, and procedures that let you qualify Simulink® and Polyspace® software verification tools for projects based on DO-178C, DO-278A, and related supplements. The kit contains tool qualification plans, tool operational requirements, and other materials required for qualifying software verification tools. With the kit, you can streamline certification of embedded systems developed using supported Simulink and Polyspace products.

The DO Qualification Kit also lets you qualify Simulink® model verification tools for projects based on DO-254. Simulink Code Inspector™ and Polyspace® code verification tools do not support HDL code, thus are not applicable to DO-254.

Tool qualification kits are available for specific versions of Simulink and Polyspace verification tools based on DO-330, Software Tool Qualification Considerations. You can modify the artifacts in the tool qualification kit for your specific project and include them in the DO-178C, DO-278A, and DO-254 certification packages submitted for certification.

Get Started:

DO-178 is the de facto international safety standard used to certify commercial avionic system software; it is increasingly used in other sectors and applications. DO-278 is derived from DO-178 and used for ground-based and space-based software. DO-178C and DO-278A are the current versions. They were published in December 2011 along with supplemental documents that extend or modify DO-178 and DO-278 guidance for software processes that employ specific technologies or techniques.

The supplemental documents are:

- DO-330, Software Tool Qualification Considerations

- DO-331, Model-Based Development and Verification Supplement to DO-178C and DO-278A

- DO-332, Object-Oriented Technology and Related Techniques Supplement to DO-178C and DO-278A

- DO-333, Formal Methods Supplement to DO-178C and DO-278A

DO-178C, Section 12.2, states that qualification of a tool is only needed if its output is not verified. It then defines tool qualification levels (TQLs) based on the tool’s impact on software life-cycle processes. DO-178C references DO-330 for tool qualification details such as the objectives, guidance, and life-cycle data required for each TQL.

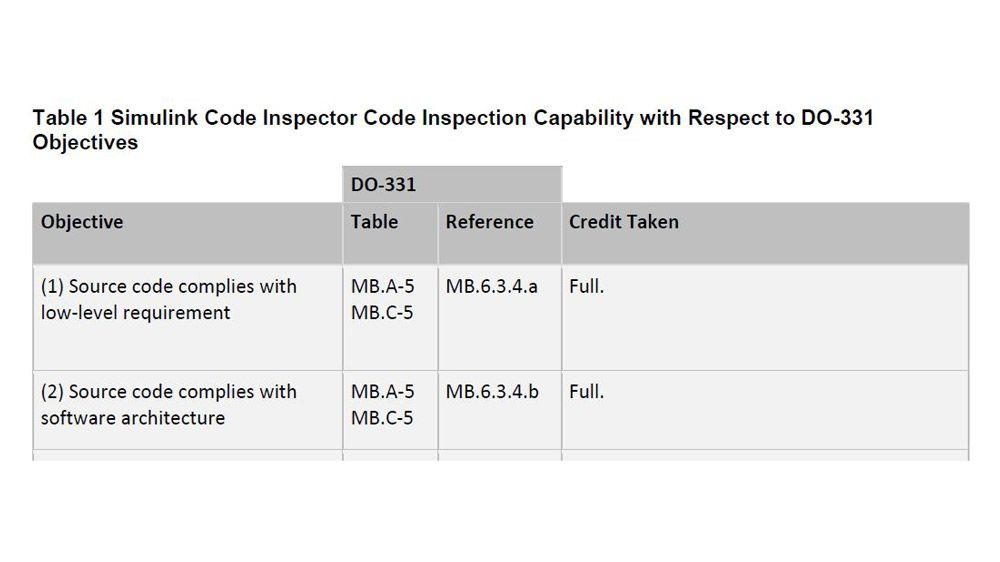

DO Qualification Kit supports DO-178C and DO-330. It also provides workflow guidance, traceability matrix generation, and other artifacts that facilitate your use of Simulink® and Polyspace® software tools for supplements including DO-331 and DO-333.

The tool user (not the tool vendor) is responsible for this qualification, and tool qualification must be done for each certification project.

DO-254 is the de facto international safety standard used to certify commercial avionic system hardware, specifically FPGAs and ASICs; it is increasingly used in other sectors and applications. It was published in April 2000.

DO-254, Section 11.4, states that qualification of a tool is only needed if its output is not independently assessed. It then defines tool qualification types based on the tool’s impact on hardware life-cycle processes. Tools can be defined as Design Tools or as Verification Tools.

DO Qualification Kit supports DO-254 for specific tools used in the verification processes. It also provides workflow guidance, traceability matrix generation, and other artifacts that facilitate your use of Simulink® verification tools.

The tool user (not the tool vendor) is responsible for this qualification, and tool qualification must be done for each certification project.

DO Qualification Kit implements the tool qualification approach specified in DO-178C. To use DO Qualification Kit, follow these steps:

- Provide certification authorities with a tool qualification plan.

- Document tool operational requirements.

- Verify that the tool satisfies tool operational requirements, and then define limitations and restrictions of the tool.

- Provide certification authorities with tool qualification results, including limitations and restrictions.

DO Qualification Kit provides guidance and information for the above steps and includes the document templates, test cases, and test procedures that you need to qualify the supported Simulink and Polyspace products.

For the supported products, DO Qualification Kit includes these artifacts:

- Tool qualification plan

- Tool operational requirements

- Test cases, procedures, and results (with supporting documentation)

You need to execute the test cases and procedures from DO Qualification Kit in your MATLAB® or Polyspace installation environment. You should then compare your generated test results with the expected results from the kit and work to eliminate any differences. Simulink Report Generator™ is required for qualifying Requirements Toolbox™, Simulink Check™, Simulink Coverage™, Simulink Code Inspector™ and Simulink Test™.

Note: Use of DO-178 qualified tools does not ensure the safety of the software or the system under consideration.

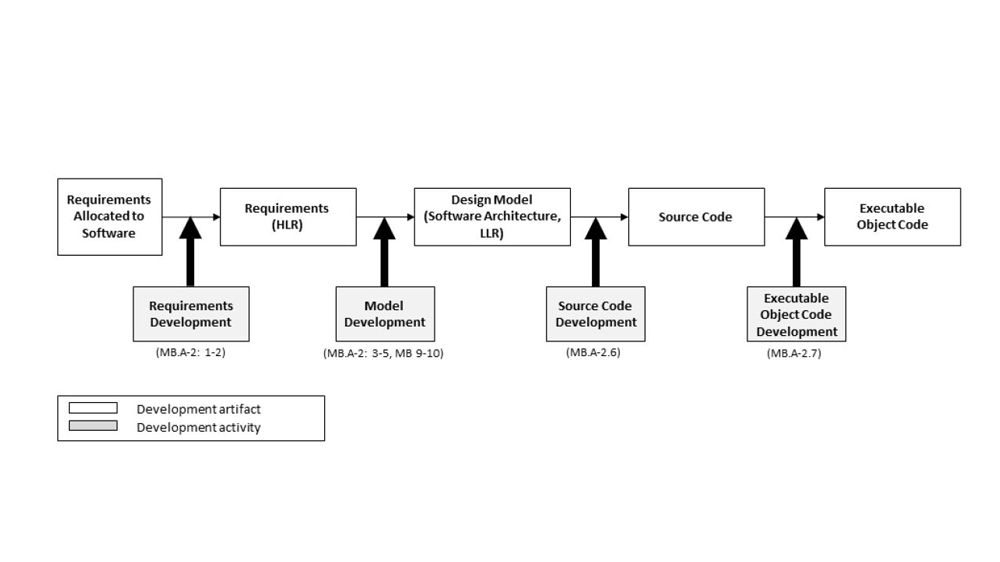

DO Qualification Kit provides detailed workflow guidance needed for developing and verifying systems using Model-Based Design. The workflow guidance describes process, methods, and tools used for each software development and verification step from high-level requirements validation to executable object code verification. It clearly identifies tool independence paths. New concepts for Model-Based Design introduced in DO-331 are explained and illustrated, including the role of simulation test cases and model coverage.

With DO Qualification Kit, you can generate a traceability matrix spreadsheet showing requirements-to-model-to-code bidirectional traceability paths and file information. You can also use DO Qualification Kit to generate a list of reported bugs that you can store and archive for key Simulink and Polyspace verification tools used for Model-Based Design.